The steel casting field is continually evolving, pushed by the demand for larger precision, improved excellent, and reduced defects. On this landscape, the stress casting device plays a vital function. However, for quite possibly the most demanding apps, a specialized kind of casting equipment is needed: the vacuum pressure casting device. this text explores the distinctive benefits of these machines, concentrating on how they enrich the precision and good quality of metal casting, specifically for cherished metals like gold and platinum.

Table of contents:

the benefits of employing Vacuum strain Casting devices for High-high-quality final results

How Vacuum tension Casting Enhances the precision of Gold, Platinum, together with other Metals

Why Vacuum stress Casting is important for superior-Precision Industries

the benefits of Using Vacuum Pressure Casting devices for prime-high-quality effects

Vacuum click here force casting machines give an important leap forward when compared with regular casting strategies. The core benefit lies from the elimination of air pockets and gas porosity within the casting. By executing the casting course of action below a vacuum, the molten metallic is allowed to stream far more freely and entirely fill the mold cavity. This results in denser, more robust castings with fewer inside defects. Additionally, the appliance of stress during the solidification phase really helps to further more consolidate the steel, reducing shrinkage and strengthening the overall top quality. This helps make vacuum stress casting perfect for producing intricate and complicated models wherever even the smallest imperfections can compromise the functionality or aesthetic attraction of the final solution.

How Vacuum stress Casting improves the precision of Gold, Platinum, and various Metals

The high value and special Attributes of treasured metals like gold and platinum necessitate Excellent casting precision. Vacuum gold casting machine know-how is specially created to fulfill these demanding requirements. The vacuum environment not simply stops oxidation from the molten metal but will also assures a clean up and steady casting process. This is particularly crucial for gold, which can easily tarnish or produce surface area defects if subjected to air through casting. Moreover, the controlled tension used in the course of solidification encourages uniform grain composition and minimizes the potential risk of cracking or distortion. This brings about castings that happen to be dimensionally precise, have great area finish, and keep the desired mechanical Attributes.

Why Vacuum stress Casting is important for significant-Precision Industries

significant-precision industries, including aerospace, health-related unit producing, and significant-finish jewelry creation, depend on vacuum force casting to obtain the stringent high quality standards required for their applications. the chance to produce castings with restricted tolerances, minimum defects, and steady product Attributes is paramount in these sectors. as an example, during the aerospace sector, vacuum pressure cast parts are used in essential motor sections where reliability and efficiency are non-negotiable. equally, in medical product manufacturing, vacuum strain casting makes certain the biocompatibility and structural integrity of implants. The benefits increase to jewelry creating likewise, the place intricate designs and flawless finishes are important for building superior-worth parts. in the end, vacuum tension casting supplies the necessary Regulate and precision to satisfy the demanding necessities of these industries. As evidenced by products and solutions much like the TAKJ-VC-W readily available at https://taeantech.com/products/takj-vc-w, these machines are precisely created to cater for the precision necessary by vacuum tension casting procedures.

In summary, vacuum tension casting equipment are indispensable resources for attaining large precision and superior high-quality in metallic casting. The mixture of vacuum setting and managed strain eliminates typical casting defects, enhances material Houses, and assures dimensional accuracy. For industries demanding the highest levels of efficiency and dependability, purchasing vacuum force casting engineering is not merely a decision but a requirement. look at the specific requirements of the application and investigate the different vacuum strain casting options available to unlock new options in metal casting and elevate the caliber of your last products and solutions.

Charlie Korsmo Then & Now!

Charlie Korsmo Then & Now! Katie Holmes Then & Now!

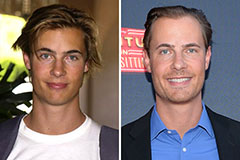

Katie Holmes Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Melissa Sue Anderson Then & Now!

Melissa Sue Anderson Then & Now!